How To Make A Hole In Glass Window

How to Drill a Hole in Glass

Updated: December. 07, 2017

And how to drill a hole in metal, ceramic tile and masonry

Drilling holes in hard stuff takes talent. Use the wrong technique or tools and y'all'll waste time, bits, materials and energy. Fortunately, talent tin exist acquired. Follow these tips and drinking glass, metal, ceramic tile and masonry will feel like balsa wood to your drill.

You might as well similar: TBD

Drilling hard stuff

Making holes in soft materials like wood is easy. You lot simply stick a standard drill bit in your drill and pull the trigger. But employ this approach on harder materials like metallic, masonry, glass or tile, and you'll waste material time, ruin drill bits and even wreck your workpiece.

This article will help yous choose the right bits and techniques for making holes in hard materials.

Getting the speed right

Running your drill too fast can cause heat buildup and ruin drill bits. Drill speed is measured in rpm (revolutions per infinitesimal). On the side of whatsoever variable-speed drill, you'll discover a sticker that lists the rpm range: "0 to 2,000 rpm," for example.

Drills don't accept exact settings or speedometers, so y'all tin can't run one precisely at the speed yous want. But if yous know your drill'due south maximum speed, you can come close enough by the audio of the motor and the experience of the trigger.

Squeeze the trigger slowly and gradually increase to full speed. Then gradually subtract speed. Practice this a couple of times and you'll develop a feel for where the trigger produces half-speed or quarter-speed and what those speeds sound like. This is easier with cordless drills, since near have high and low ranges.

Drilling into glass

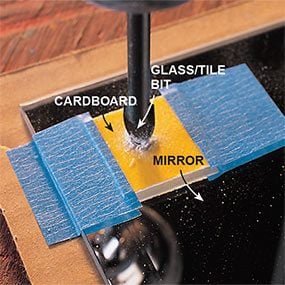

Drilling a hole in a pane of glass or a mirror is simple. The key is to apply a carbide bit made especially for glass and tile (see photos). You lot'll find these bits at nearly home centers alongside other drill bits or ceramic tile tools.

Considering glass is extremely smooth and hard, the bit volition want to wander as you start drilling. To give the bit a foothold, record a small flake of dense cardboard (similar cereal box cardboard) to the glass. Begin at very low rpm to create a dimple in the glass, and then remove the paper-thin and continue at about 400 rpm. If you're drilling on a horizontal surface, you can pour a little oil on the area.

Make sure the glass is firmly supported on the backside and place only very light force per unit area on the drill; press besides difficult and yous'll crack the glass. The fleck creates a clean hole on the side it enters, but usually chips the edges of the pigsty on the other side.

Note: Y'all can't drill tempered glass.

Drilling into metal

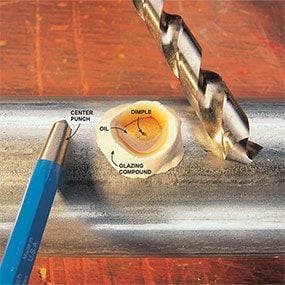

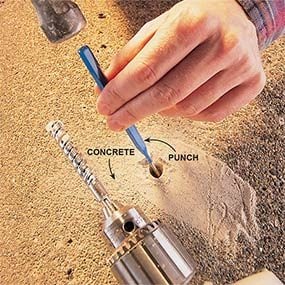

Nearly of the drill $.25 you use for wood will likewise bore into metallic (encounter photos above). Just a spinning glass drill bit tends to wander across metal's hard, polish surface earlier information technology begins to dig in. You lot tin requite the bit an verbal starting point using a center dial and a hammer. The dial creates a tiny dimple that keeps the scrap in place (come across photos higher up). With a soft metallic like aluminum, you can apply a nail instead of a punch.

A niggling oil helps you drill faster and keeps the bit cooler, so information technology stays sharp longer. There are special drilling oils, but you can use just about anything—motor oil, manual fluid, kerosene, even cooking oil. On a slanted surface, keep the oil in place with a ring of plumber's putty, glazing compound or even Play-Doh.

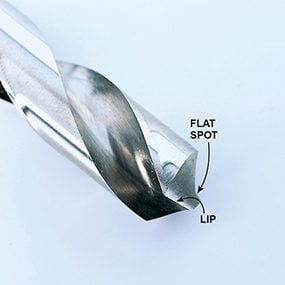

If you're drilling holes larger than one/four in. through metallic more than than 1/16 in. thick, save time by boring smaller airplane pilot holes first. The tips of many drinking glass drill bits accept a flat spot that doesn't slice into metal nearly as well as the sharp outer "lips." By kickoff drilling a pilot hole with a pocket-sized scrap—about the same diameter as the flat spot on the larger chip—you allow the larger bit to cut faster. Seal the underside of the hole with duct record to keep oil from draining away.

Use house, steady force per unit area and moderate speed (600 to 700 rpm) until yous're almost washed. Equally the bit breaks through the other side of the metal, the lips can grab the thin remaining edges. This causes the workpiece (or drill) to spin and might go out yous with a broken glass drill bit or workpiece or even injuries. You lot can avoid all of this if you ease off the pressure and become to full drill speed just before breakthrough. To be on the safe side, ever clamp workpieces in place.

Drilling into ceramic tile

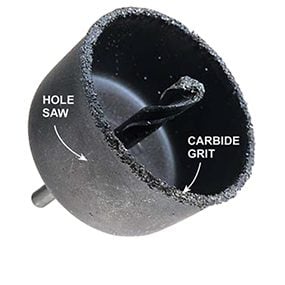

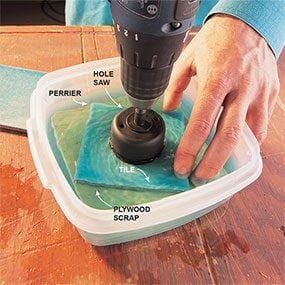

Tile varies profoundly in hardness. You can drill some types of tile using a standard carbide masonry bit. Harder tile requires the chip yous'd use for drinking glass (see "Drilling into Glass" above). In either hard or soft tile, you tin make a hole large plenty for plumbing fixtures with a carbide grit hole saw (run across photo in a higher place), available at domicile centers and tile suppliers.

To get a hole started without wandering, use the paper-thin trick shown in "Drilling into Drinking glass" in a higher place. The hole saw works best at low speeds (100 to 200 rpm). It cuts slowly and creates a lot of heat, sometimes enough to crack the tile. To prevent "heat daze," immerse the tile in a shallow pool of h2o. Water keeps everything cool and actually helps the hole saw cut a picayune faster. Place a fleck of plywood under the tile so you lot don't drill through the pan.

Alarm: Water and electricity are a dangerous combination. Plug your drill into a GFCI-protected outlet or utilise a cordless drill.

Drilling into masonry

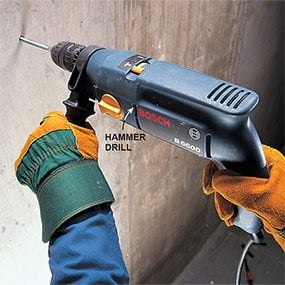

Most forms of masonry—mortar, stucco, brick and concrete block—are fairly piece of cake to drill. Use a carbide-tipped masonry bit (see photo above), push hard and run your drill at near ane,000 rpm. Pull the bit out of the hole occasionally to clear out the pulverisation created past drilling. To make drilling a large hole easier, begin with a small bit and piece of work upwardly: 1/4 in. to iii/viii in. to 1/ii in., for example.

When you're using a standard drill, physical presents problems that other types of masonry don't because it'due south full of small stones. Some of these stones are soft enough to drill through easily. Only if you lot striking a hard one, information technology volition stop your progress dead. When yous hit a hard stone, keep drilling for a few seconds—you might break through. If non, simply move over and try another spot. If the hole has to be precisely placed, employ a punch or small chisel to break upward the stone.

A standard corded or cordless drill is fine for drilling a couple of holes in masonry. But if you accept to make lots of holes, utilize a hammer drill to speed up the job (see photo to a higher place). Hammer drills not only spin the bit but also hammer it forward thousands of times per minute. Hammer drills are available for purchase at home centers and tool stores or yous tin can rent one.

Required Tools for this Projection

Have the necessary tools for this DIY project lined up before y'all start—you'll salvage time and frustration.

Required Materials for this Projection

Avert last-minute shopping trips by having all your materials ready alee of fourth dimension. Here's a list.

Originally Published: December 07, 2017

Source: https://www.familyhandyman.com/project/how-to-drill-a-hole-in-glass/

Posted by: nixonyones1946.blogspot.com

0 Response to "How To Make A Hole In Glass Window"

Post a Comment